What Is Torque Calibration?

It is recommended that torque transducers be calibrated periodically to ensure their accuracy. This process involves comparing the measurement values of the equipment against a universally recognized standard of accuracy that has been predetermined. The purpose of this procedure is to make sure the instruments you use are performing within the manufacturer’s recommended tolerance. Without proper calibration, your equipment may not provide the accurate readings you need to keep your equipment running at its most effective and efficient.

The Torque Calibration Process

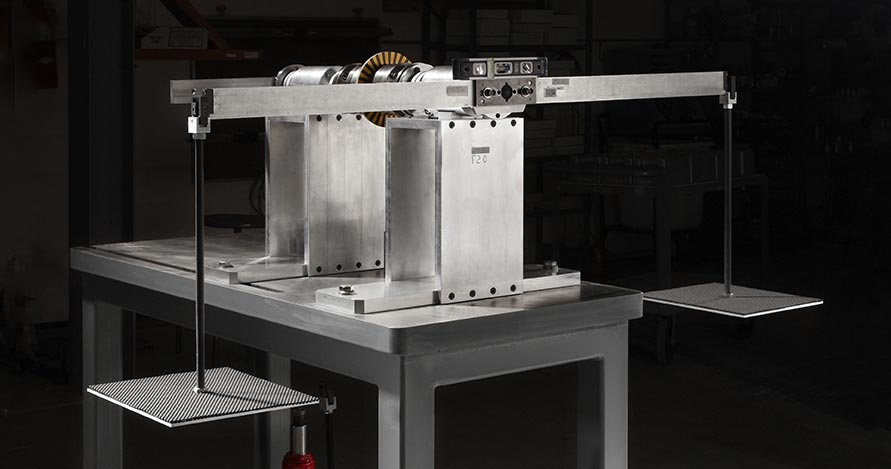

There can be variations in the defined procedures for performing the actual calibration. They may be based on the manufacturers’ recommendations, relevant ANSI/ASME standards, federal requirements or customer requests. Regardless, they all require the application of a precise, known torque load to the sensor. This loading can be generated through the use of a lever arm of defined length and the hanging of precise weights off of this lever arm. Alternatively, the load can be applied to a lever arm using a hydraulic cylinder. In this case, a precise reference standard transducer is required to accurately measure the applied load. The specific process to calibrate these instruments may be different from case to case, the end result is the same — greater accuracy from the specified equipment.

Our Accreditation

Himmelstein’s Torque Calibration Laboratory is accredited to ISO 17025:2017 by NVLAP, an arm of the NIST, lab code 200487-0. Select the links below for a copy of the NVLAP Certificate and Accreditation Scope.

Certificates of Conformance are available upon request from the factory.

Our Torque Tester and Calibration Capabilities

Calibration Services for Torque Transduces from Virtually Any Manufacturer

- 10-point calibration

- 10-point calibration, as found/as left

Calibration Services for Torque Transducers from S. Himmelstein and Company Only

- 10-point calibration with temperature compensation

- 10-point calibration, as found/as left with temperature compensation

Speed (RPM) Calibration Services

mV/V Calibration Services